Stamping tools

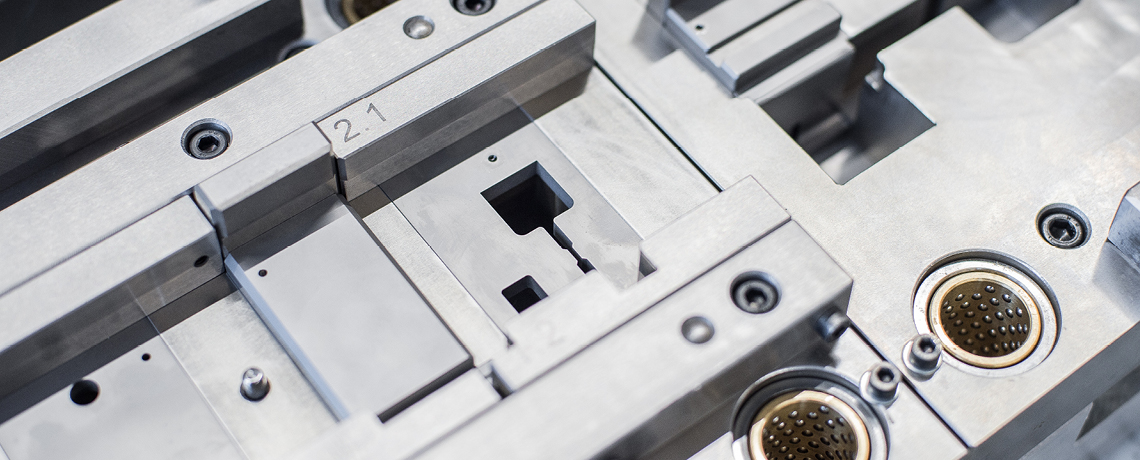

Perfect stamping tools are the cornerstone for successful production. A stamped part is formed by stamps and dies and can only be produced as precisely as the tool specifies. That is why we focus on maximum precision and also offer highly complex designs. Our goal is to combine economic efficiency with functionality. Various materials are used for this purpose. Thus, non-load-bearing parts are kept lighter, while the components actively involved in the stamping process are all made of hardened tool steel. In addition to reducing costs, we also increase the service life.

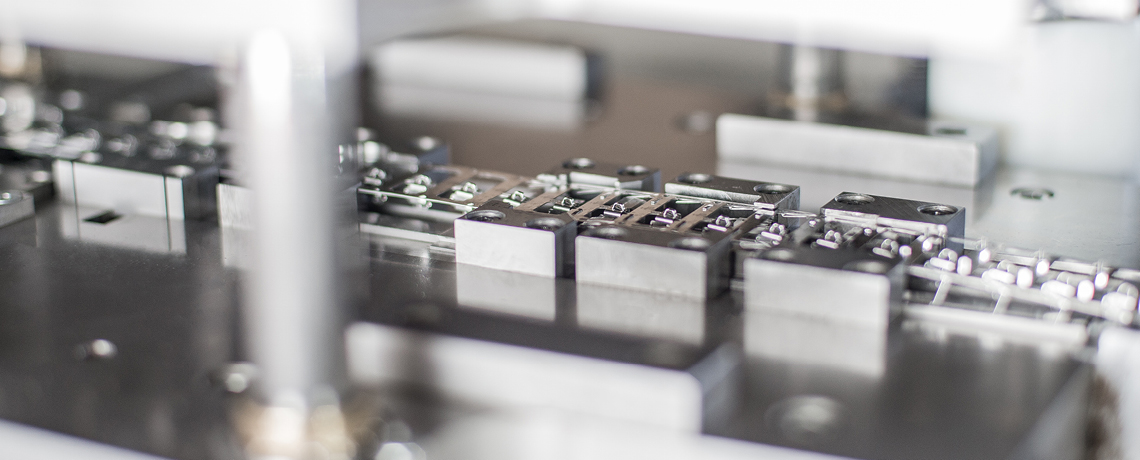

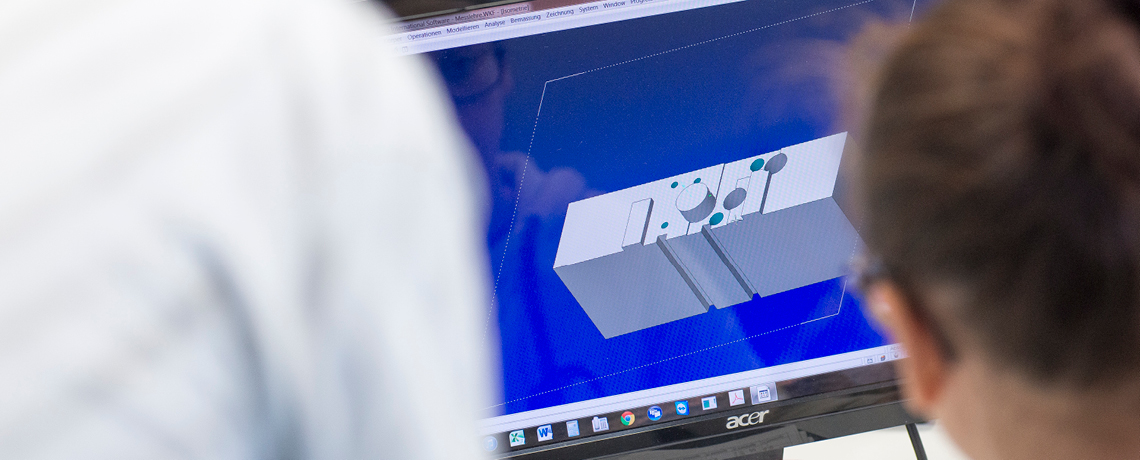

Our modular design enables large tools to be converted or maintained quickly and easily. The result is shorter set-up times and faster machining times. In addition, extensive tool monitoring ensures smooth operation with consistent quality.

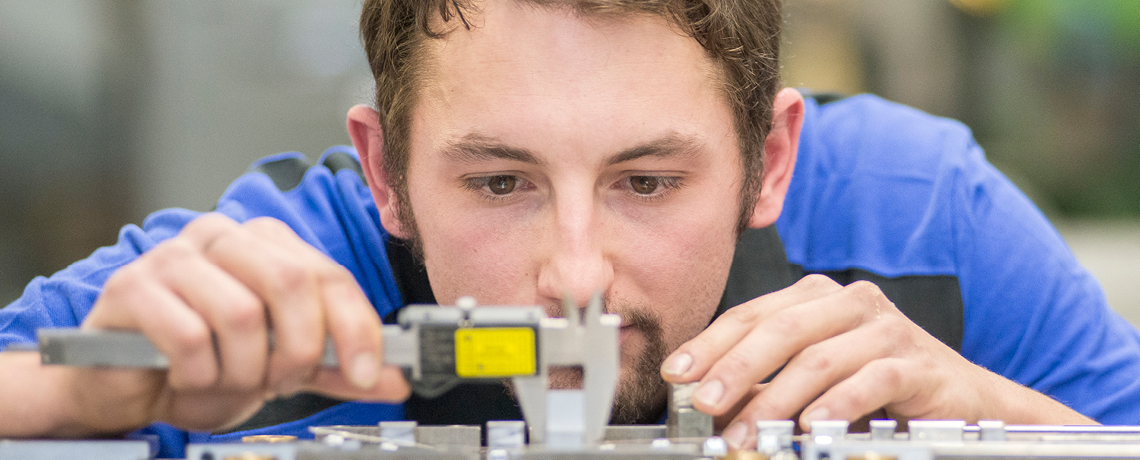

A constant target/actual comparison already takes place during the development process. State-of-the-art precision mechanics look after the tools in three-shift operation. Deviations and errors can thus be detected and corrected at an early stage.

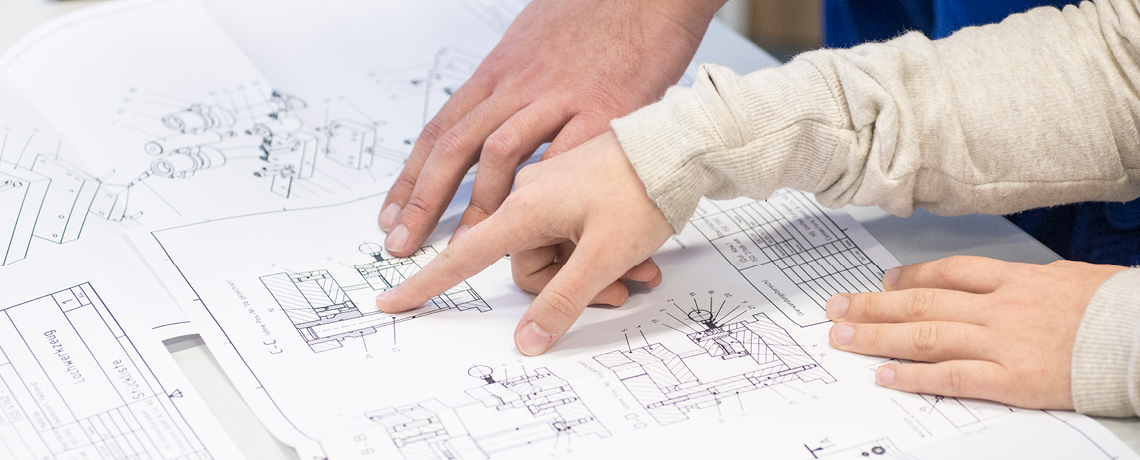

The tool manufacture associated with production enables us to react quickly. This means that there is a direct exchange from the precision mechanics to the plant operator.

Many years of experience with large and small tools for electrical contacts create optimum conditions for efficiently implementing your new product in the simplest way.