Testing technology

Our products have to pass a strict, internally standardised testing process before they leave the company in order to meet our demands for quality and reliability.

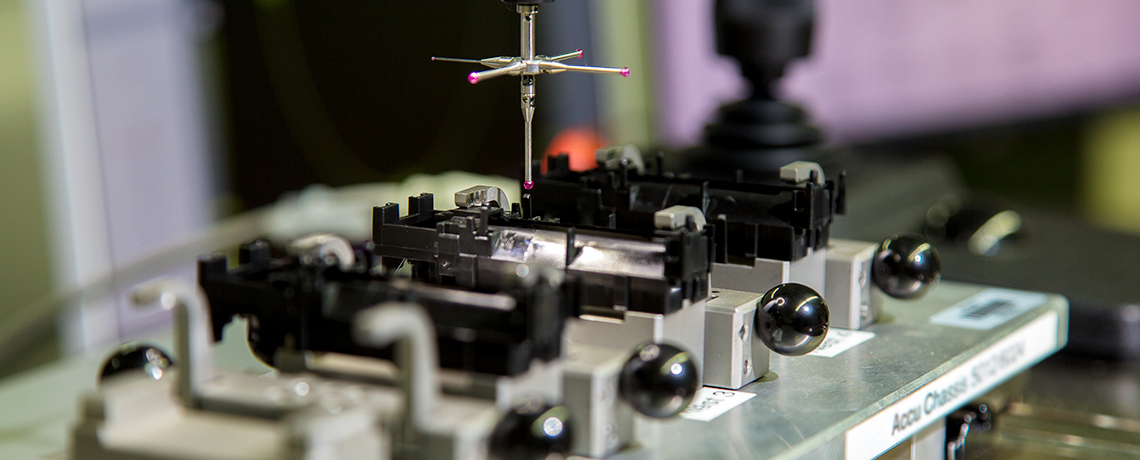

An essential part of the inspection chain are automated measuring devices from the manufacturers Vester, OTTO Vision, Keyence, Werth-Messtechnik and Garant. Integrated into the production process, they guarantee 100% control without any loss of speed.

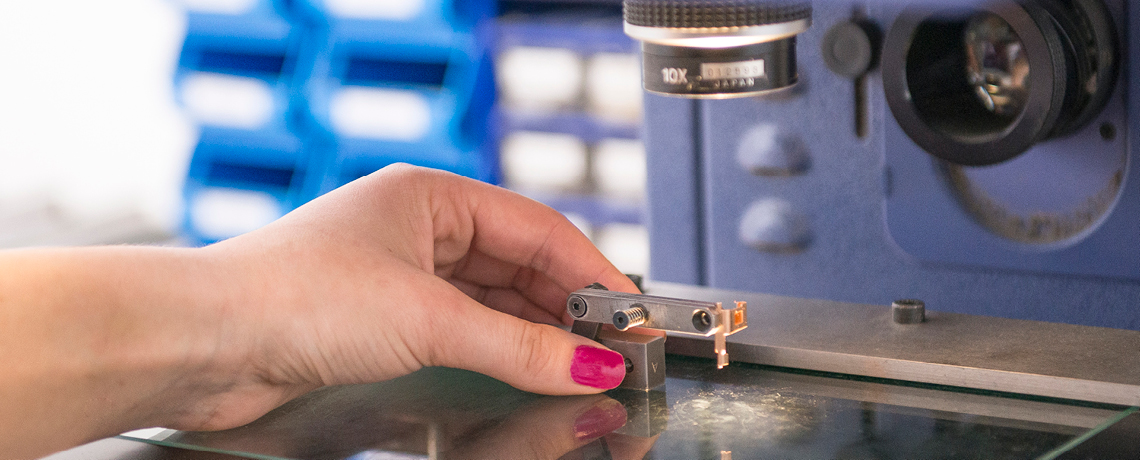

A climate-controlled measuring laboratory with trained personnel is available for all other products that are unable to be technically monitored in the manufacturing process. We can thus test individual parts using our 3D measuring machines as well as our self-configured test devices.

We invest continuously to ensure that we always remain at the cutting edge of technology and competitive. A mix of in-house developed and purchased devices creates the basis for ever better test automation. Highly qualified employees ensure the appropriate operation and setting.

In order to live up to our zero-defect philosophy, our departments develop custom-fit solutions to meet customer-specific requirements according to the highest quality standards.

Our services range from in-house development and design, construction of the test fixtures through to commissioning and handover to series production.

The spectrum ranges from simple assembly jigs and assembly workstations, operating equipment and tools, to semi-automatic testing and assembly processes.

To this end, the following test methods are used, amongst others:

– continuity and polarity reversal tests

– short circuit tests

– high voltage tests

– push-back and latching control

– visual colour control

– presence and contour checking

– optical and tactile measurement technology